Scope and Application

It can be used in these areas such as metallurgical industry, coal-mining industry, building, chemical and grinding industry, etc.

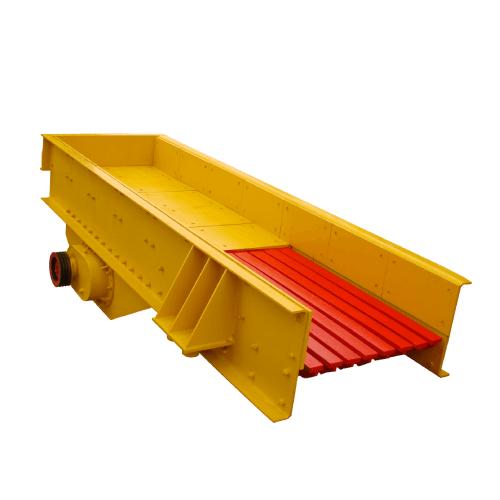

Working Principle

The vibrating feeder, also known as the vibrating feeder, is mainly responsible for the uniform continuous or quantitative feeding of bulk, granular and powdered materials from the storage warehouse or funnel to the receiving equipment in the production process.

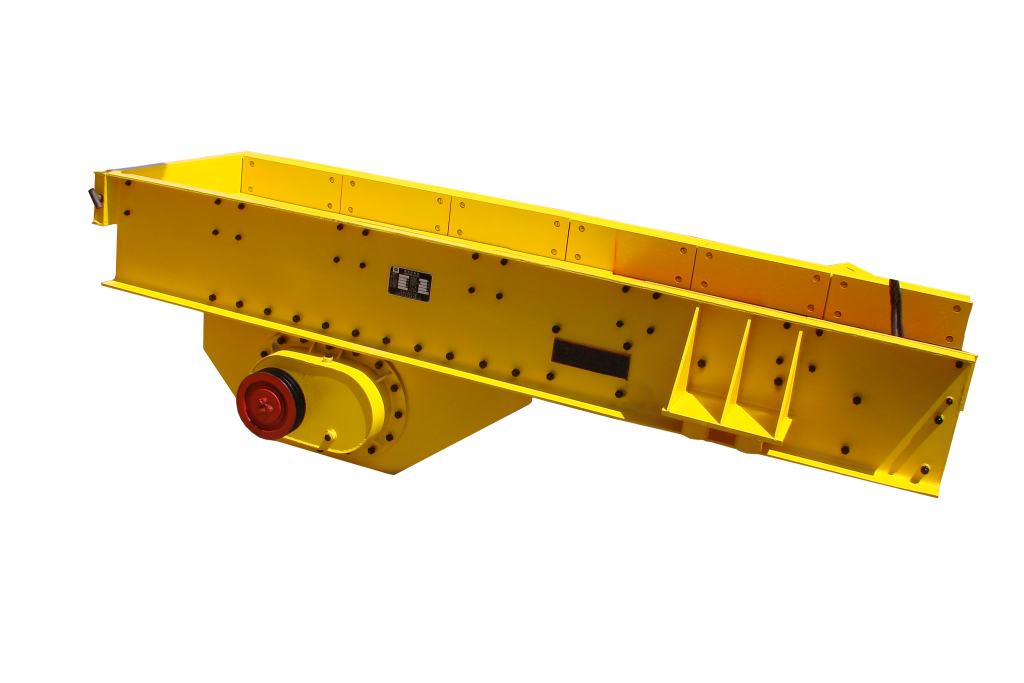

Components

Feed End

The feed end is the starting point of the trough where materials are introduced into the system.

Discharge End

The discharge end is where materials exit the system at the lower end of the trough.

Eccentric Weight

The eccentric weight, attached off-center, generates oscillations by creating an unbalanced rotation.

Reactor Springs

Reactor springs are the main springs in the vibrating system that provide continuous energy.

Isolation Springs

Isolation springs support the feeder while protecting the structure from vibrations.

Components

Tuning Springs

Tuning springs adjust the feeder’s natural frequency for optimal operation.

Dynamic Balancer

The dynamic balancer reduces forces transmitted to the structure by counteracting drive unit forces.

Liner

Liners are wear-resistant surfaces within the trough to enhance durability and manage material flow.

Screen

A screen separates fine from coarse particles, ensuring size-specific output.

Grizzly

The grizzly is a heavy-duty screen for coarse material separation.

Specification

| Model | Input Size (mm) | Capacity (t/h) | Power (kw) | Chute size (mm) | Weight (ton) | Dimension (mm) |

| GZD-180*80 | 300 | 30-80 | 2 x 1.5 | 1800 x 800 | 0.8 | 2200*1100*800 |

| GZD-200*120 | 300 | 80-500 | 2 x 2.2 | 2000 x 1200 | 0.9 | 2000*1200*855 |

| GZD-300*90 | 300 | 40-100 | 2 x 2.2 | 3000 x 900 | 1.5 | 3050*1430*1550 |

| ZSW-380*96 | 500 | 90-200 | 11 | 4200 x 1100 | 5.0 | 3882*2224*2121 |

| ZSW-420*110 | 580 | 150-350 | 15 | 4900 x 960 | 5.5 | 4250*2500*1365 |

| ZSW-490*110 | 580 | 180-380 | 15 | 4900 x 1100 | 5.32 | 4957*2500*1365 |

| ZSW-490*130 | 750 | 250-450 | 22 | 4900 x 1300 | 5.9 | 4957*2580*2083 |

| ZSW-600*130 | 750 | 450-800 | 30 | 6000 x 1300 | 7.8 | 6082*2580*2083 |

| ZSW-600*150 | 800 | 600-1000 | 30 | 6000 x 1500 | 8.67 | 6082*2660*2400 |