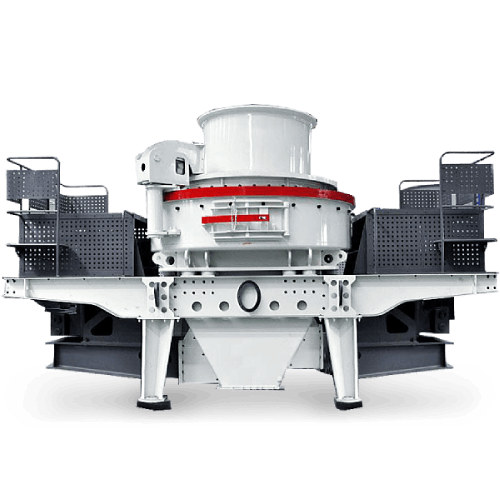

Vertical Impact Crusher

Vertical impact crusher is a new crushing concept of equipment, mainly used for soft or medium hard and extremely hard crushing, shaping.

Input size:

<60mm

Power:

22-440kw

Capacity:

12-360t/h

Scope and Application

The equipment, with a history spanning over three decades, has been extensively utilized in various sectors such as metallurgy, non-metallic ore processing, fireproof materials, bauxite, diamond dust, glass raw materials, construction materials, artificial sand, and a wide array of metallic ores.

metallurgy

ore

fireproofing

bauxite

diamond dust

Its advanced design allows for efficient processing of hard materials, setting it apart from competitors and solidifying its status as a preferred choice for challenging material processing tasks.

Working Principle

The working principle of the vertical shaft impact crusher begins with the initial impact stage, where stones are crushed by colliding with one another. The material then enters the impeller cavity and is subjected to a strong centrifugal force that propels it upwards.

As the material ascends within the impeller cavity, it encounters other falling materials, creating a dynamic interaction.

The force of these collisions generates a vortex between the impeller and the shell, causing the materials to strike each other multiple times.

Through the repetitive impacts within the vortex, the materials undergo a process of progressive size reduction.

The continuous collisions against the impeller and shell break down the stones into smaller and smaller pieces.

The crushed stones, now in a smaller size, are directed towards a vibrating screen, which separates the material based on the desired output size. Satisfactory material that meets the size requirements is transported to a sand washing machine for further processing.

Any material that exceeds the specified size is recirculated back into the sand maker for additional crushing. This ensures that all output meets the customer’s requirements and that only the appropriately sized material proceeds to the next stage of processing.

The output sizes from the vertical shaft impact crusher can be adjusted according to customer requirements, providing flexibility in the production process. If the input material’s size is larger than the design allows, additional crushing equipment may be integrated to ensure effective processing.

Working Features

The rotor design of the vertical shaft impact crusher has been meticulously optimized, featuring a deep-cavity configuration that increases the material throughput by an impressive 30%.

This enhancement allows for more efficient processing and higher output rates, catering to the demands of large-scale operations.

The final product from the vertical impact crusher boasts a fine and cubic shape, which is highly desirable in various applications.

The fineness modulus is adjustable, and it has been proven that the reshaping achievement is increased by 30%, ensuring a high-quality end product.

The round guard plate is designed for efficient use, allowing for a U-turn utilization after partial wearing.

The spread dish is a dual-purpose component that facilitates easy switching between two feeding methods.

This adaptability allows the crusher to handle different feed materials and conditions, enhancing the crusher’s versatility and functionality.

The output sizes from the vertical impact crusher can be tailored according to customer requirements, ensuring that the final product meets specific application needs.

This customization is made possible by adjusting the rotor speed and the configuration of the crushing chamber.

For input sizes larger than the designed size, the vertical impact crusher can be integrated with other crushing equipment to form a complete crushing circuit.

This integration ensures that oversized materials are effectively processed and resized.

Parameters

| Model | Input Size (mm) | Power (r/min) | Speed (r/min) | Capacity (t/h) | Dimension (mm) | Weight (kg) |

| PCL-600 | 35 | 22-55 | 2000/3000 | 12-30 | 2500*Φ1600*2260 | 5600 |

| PCL-750 | 45 | 45-90 | 1500/2500 | 25-55 | 2780*Φ1800*2700 | 7300 |

| PCL-900 | 50 | 90-180 | 1200/2000 | 55-100 | 3900*Φ2160*2770 | 12100 |

| PCL-1050 | 60 | 150-264 | 1000/1700 | 100-160 | 4660*Φ2450*3660 | 16900 |

| PCL-1250 | 60 | 264-440 | 850/1450 | 160-300 | 5600*Φ2950*4000 | 22000 |

| PCL-1350 | 60 | 320-440 | 800-1193 | 200-360 | 5340*Φ2940*3650 | 26000 |