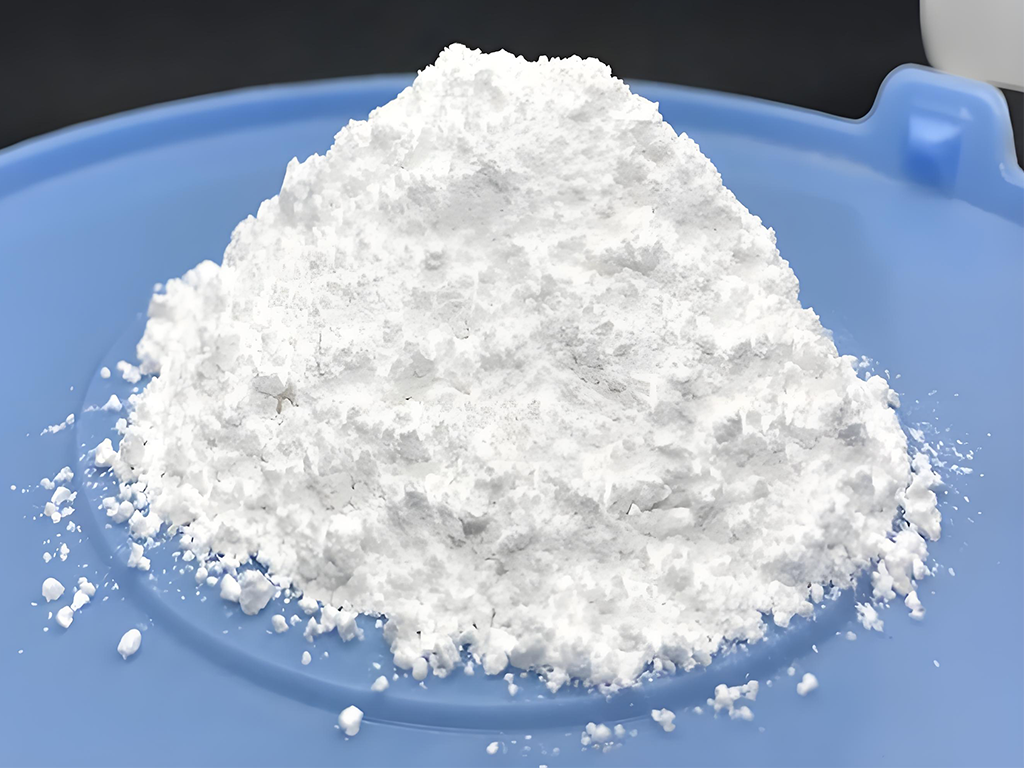

Talcum powder, known for its excellent physical and chemical properties, plays a vital role in the paper industry. Clirik talc grinder fully showcases the characteristics of talc powder, bringing revolutionary improvements to the paper industry.

Talc Material Features Overview

Talc has the characteristics of lubricity, fire resistance, acid resistance, insulation, high melting point, etc. Its layered crystal structure makes it have the tendency to split into scales and special slipperiness. Therefore, talc has become an indispensable material in many industries.

Clirik Talc Grinder Introduction

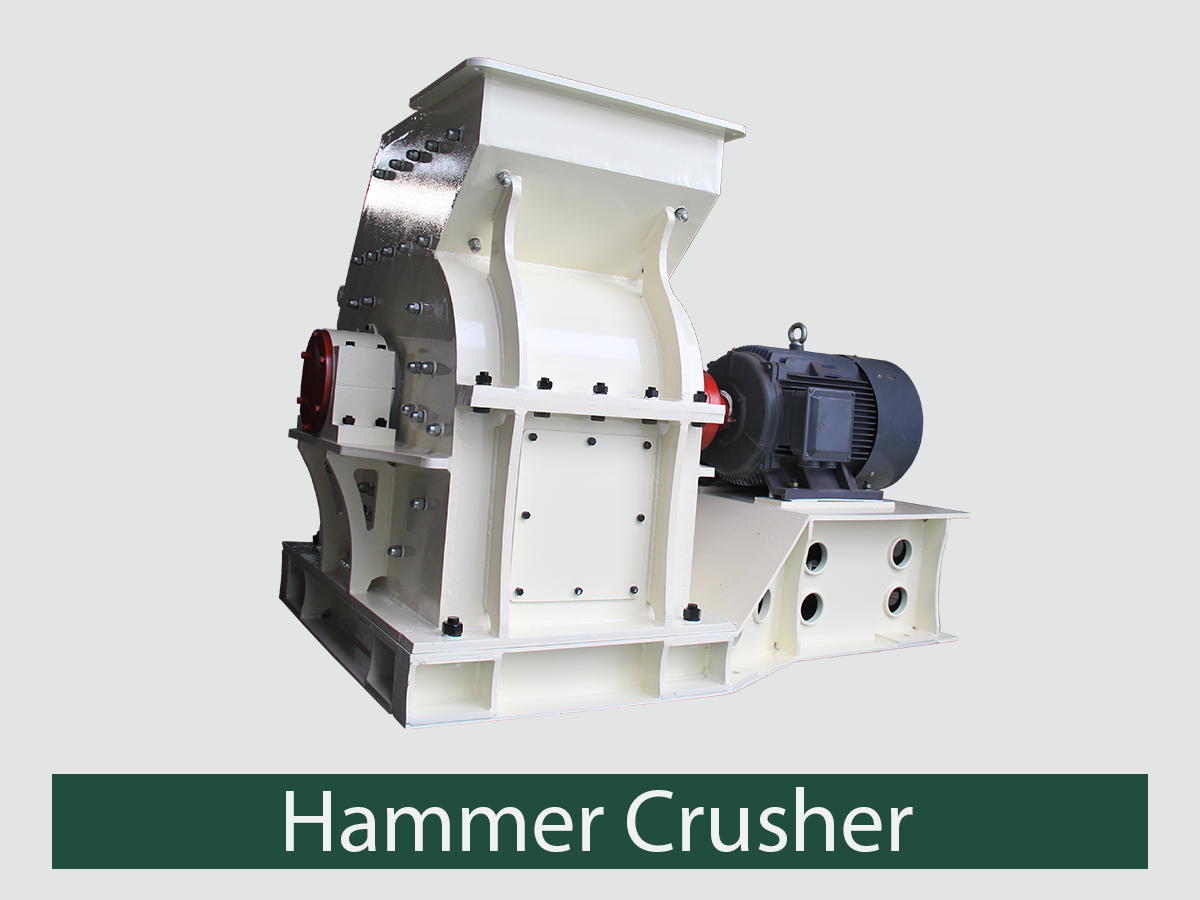

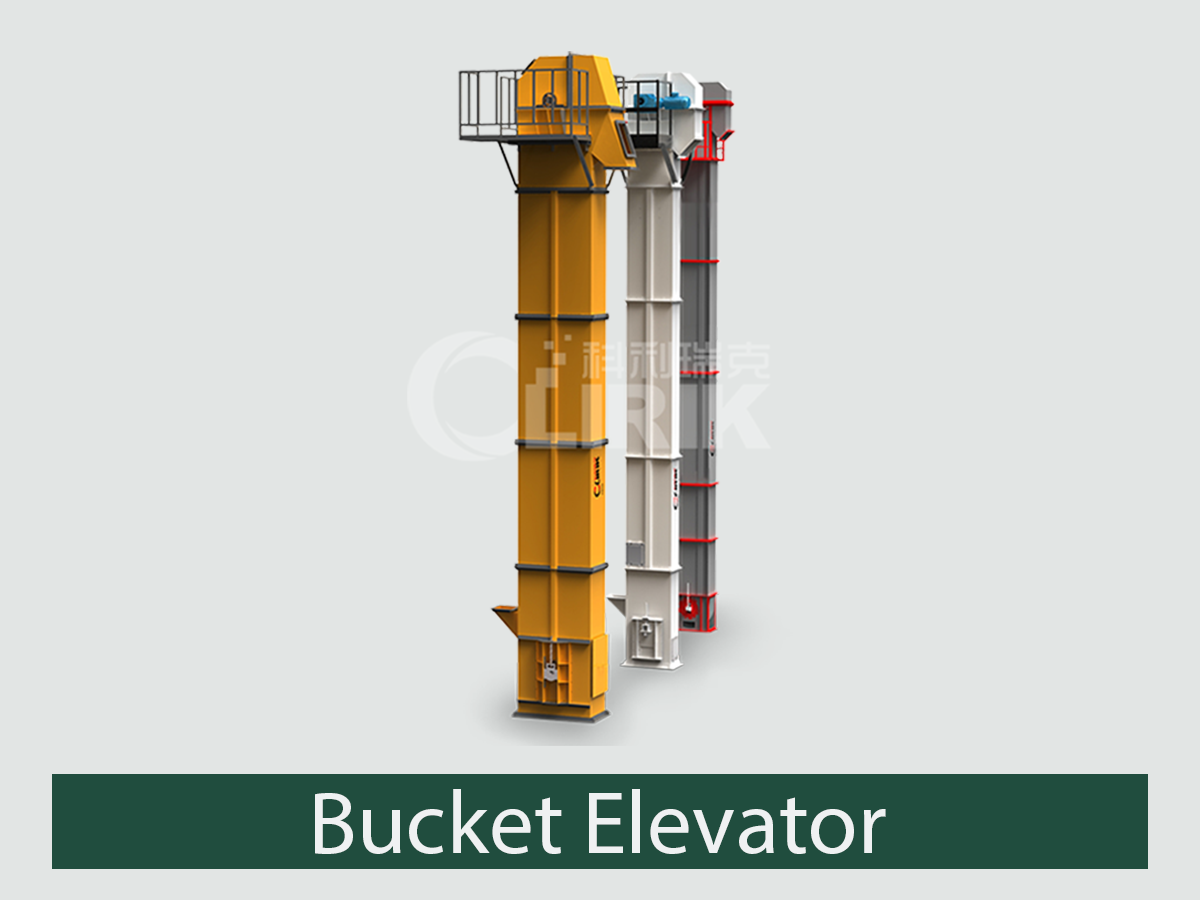

Clirik talc mill is suitable for ultra-fine grinding of low and medium hardness materials. The grinding equipment can process talc and other materials into fine powder between 325-3000 mesh. The production capacity of Clirik mill is 0.7-7.5 tons per hour.And the grinder configuration includes Micro Powder Grinding Mills, Hammer Crushers, Bucket Elevators, Vibrating Feeders, etc., ensuring efficient and stable production.

Advantages of Talc Powder in the Paper Industry

01 Improving Paper Quality

Talc powder’s layered structure and softness help increase filler retention, improve paper opacity, smoothness, and printability, and give paper higher ink absorption.

02 Stable Chemical Properties

Talcum powder’s chemical stability makes it suitable for paper-making under acidic and neutral conditions, providing greater flexibility when used with calcium carbonate.

03 Cost Savings

The hydrophobicity (lipophilicity) of talc reduces the consumption of dyes and saves costs. It can be used as a resin, adhesive inhibitor and deinking agent for waste paper.

04 Enhancing Sizing Effects

Talcum powder combines well with sizing agents, improves sizing retention, and reduces paper absorption, preventing printing ink from penetrating the paper.

05 Reducing Printing Pressure

Talc powder’s low coefficient of friction helps make the coating surface smooth and flexible, reducing coating breaks and printing pressure.

06 Enhancing Printing Quality

As a high aspect ratio coating pigment, talc powder has excellent fiber coverage and printing effects, improving the quality of gravure printing.

07 High Finishing Degree

Talc powder’s special lubricity allows coated paper to achieve a high degree of finishing on calendering machines, reducing the use of lubricants in coatings.

Clirik’s talc grinder not only enhances the physical and chemical properties of talc powder but also provides customized grinding solutions according to the needs of the paper industry. By using Clirik’s grinding equipment, paper companies can produce higher quality paper while reducing production costs and increasing market competitiveness.