Working Features

★ The equipment can solve the difficult problem of high fineness sand loss and low powder content.

★ Polyurethane in the cyclone has improved the life oh the whole equipment, which enables to finish the job of slurry concentration and liquid clarification.

★ The maximum fine grain materials quantity recovered from the total effluent is 85%, so it has the incomparable technology and economy advantage.

★ As the fine sand is recovered efficiently, the workload of sedimentation tank is reduced, and so does its clean cost.

★ The nature stock time of the fine sand is reduced, so it can be sold immediately.

Working Principle

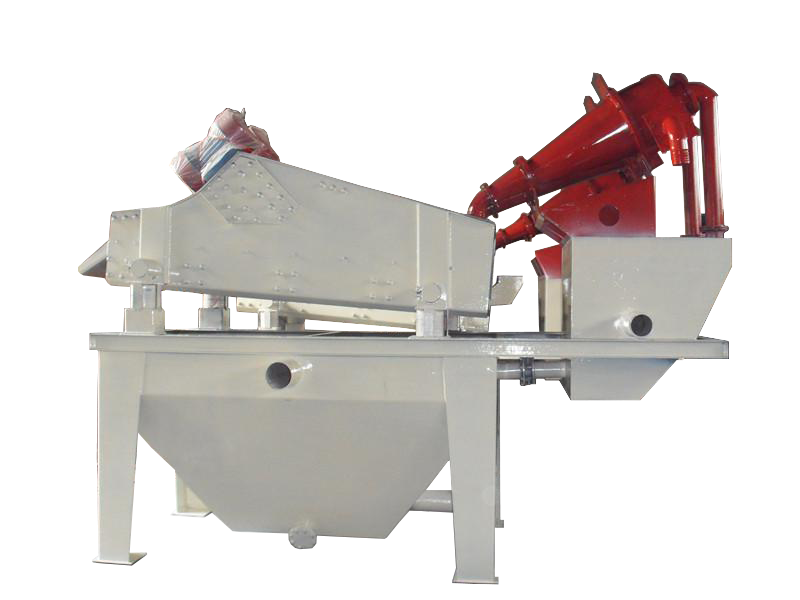

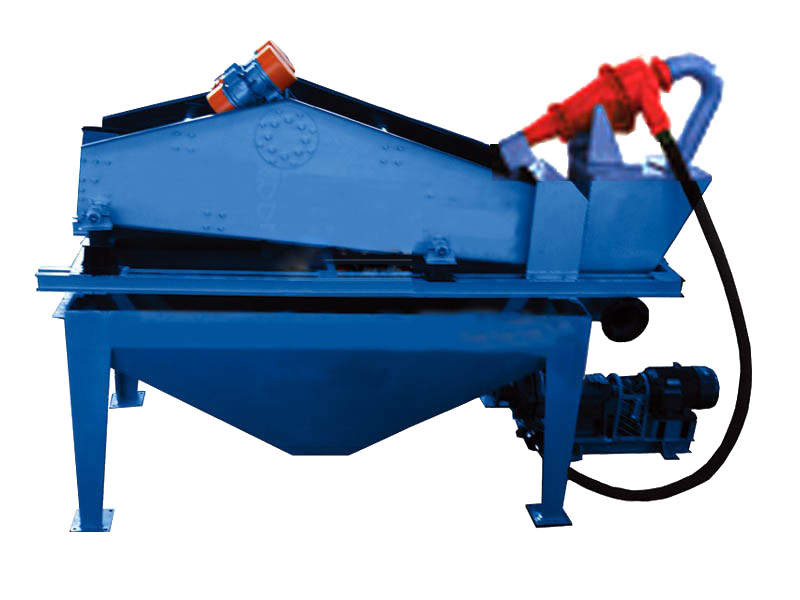

Structure

The system is composed of motor, pump, cyclone, vibrating, pool, recycling box.

function

● Washing

● Dehydration

● Screening

The compound of sand and water is transported to cyclone, the sand that centrifugal classification concentrate is provided to the vibrating screen by the heavy grit, and sand and water are effectively separated after vibrating screen dehydration.

Through recycling box, fine sand and mud and so on are transported again to the pool, and then they are exhausted from the exit when the liquid surface of pool is too high.

The material weight concentration recovered by the vibrating screen is 70%-80%.

Adjusting fineness module may come true by changing the pump rotation rate, changing pulp concentration, adjusting the flooding water yield, or changing the grit mouth.

Main Specification

| Model | Pump Powder | Pump Material | Specifications (mm) | Sieve Dehydration Material | Sieve Dehydration Powder (kw) | Capacity (m3/h) | Weight (kg) |

| LZ250 | 7.5-11 | Cr26 | 250 | PU | 2*0.55 | 30-80 | 2050 |

| LZ300 | 11-15 | Cr26 | 300 | PU | 2*0.75 | 40-100 | 2200 |

| LZ350 | 15 | Cr26 | 350 | PU | 2*0.75 | 70-130 | 2555 |

| LZ550 | 15-22 | Cr26 | 550 | PU | 2*1.1 | 100-220 | 3250 |

| LZ650 | 18.5-30 | Cr26 | 650 | PU | 2*1.1 | 120-272 | 3945 |

| LZ750 | 37-55 | Cr26 | 750 | PU | 2*1.5 | 180-350 | 4900 |

| LZ900 | 55-65 | Cr26 | 900 | PU | 2*2.2 | 250-500 | 5650 |