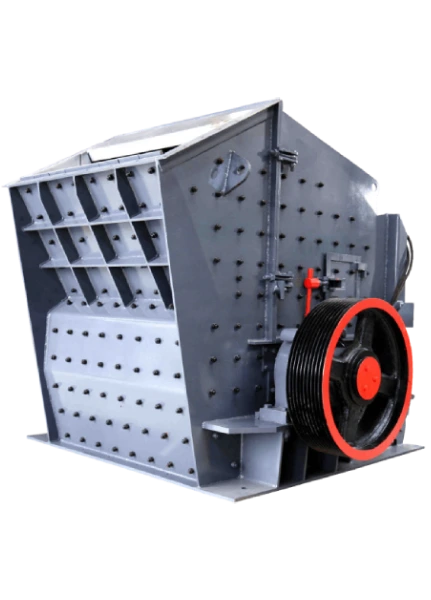

Impact Crusher

The impact crusher is a high-performance impact crusher developed by our company using international advanced technology. It is widely used in various ore crushing, railways, highways and the production of artificial sand and gravel in the construction industry.

Feeding size:

<350mm

Capacity:

90-350t/h

Seriers:

PFW / PF

Introduction

PFW series European version impact crusher is a new high-performance hydraulic impact crusher developed using internationally advanced impact crusher technology. Its main purpose is to make the maintenance operations of the impact crusher easier, while improving the life of wearing parts and equipment performance, and reducing the processing cost of soft materials.

In addition to the innovative design of the rotor and impact frame, the PFW series European version impact crusher also introduces a hydraulic system for adjustment and jacking operations. At the same time, coarse crushing and medium crushing models are launched according to user needs for different operating requirements.

Working principle

Euro-style impact crusher crushes materials with impact force. When the materials enter the blow bar area, they are crushed by the high-speed rotor, and then thrown to the impact plates on the rotor for secondary crushing. Next material rebounds to the rotor and is crushed again.

This process is repeated until the material is crushed to the required particle size and discharged from the lower part of the machine.

The size and shape of the final product can be changed by adjusting the gap between the impact plate shelves and the rotor.

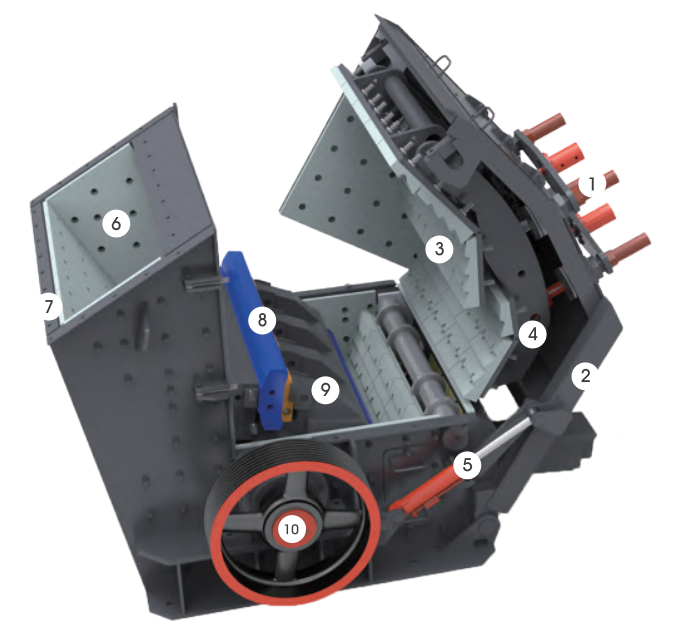

Detailed Structures

1. Hydraulic Regulation Device

2. Rear Frame

3. Impact Plate

4. Impact Rack

5. Hydraulic Jacking Device

6. Lining Plate

7. Front Frame

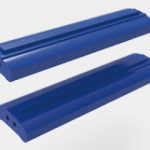

8. Hammer Bar

9. Rotor

10. Bearing House

Characteristic Feature

Advanced manufacture process and high-end fabrication material

The important components of the equipment are made of advanced machining and hot treatment processes. The Counterstrike board is cast by highly wear-resistant material and the impact face is provided with a lining structure, largely improving the wear-resistance property of the impact plate. The board hammer is poured by the process integrating with high-chrome material and wear-resistant material and processed by the rigid thermal treatment, having fine machine impact resistance and thermal impact resistance properties.

It makes the fullest use of the Hammer bars with a symmetric design, which can extend the working life about two times than the old design.

Heavy rotor design and tight test method

The European Style impact crusher adopts a rigid heavy rotor to gain more rotary inertia and counterforce to increase the crushing capacity; and is tested by the tight test method on the defect on the surface, near-surface, and inner surface to ensure its high quality and improve the rotor performance.

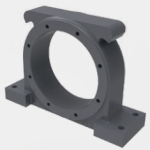

Overall type cast steel structure bearing base

The overall cast steel bearing base is fully matched with the crusher, and largely increases the radial strength of the bearing base and improves anti-load resistance capacity; while the split type bearing base is out of these advantages.

Reliable wedge fixing mode

The flat hammer of the PFW impact crusher is fixed on the rotor by a group of wedge blocks. The wedge block tightly locks the flat hammer from horizontal and vertical directions and needs more fastening torque to enable the flat hammer installed simply and conveniently and eliminate abrasions from the flat hammer fixed by bolts.

Spring safety device

When iron or other hard material that can’t be crushed, is fed into the crushing chamber, the front and rear impact shelves will be pushed back, so the hard material will be discharged, and the impact crusher resume production and eliminate the blocking risk.

Hydraulic jacking device and hydraulic regulated discharging port

PFW series impact crusher is installed with a hydraulic system on both sides. This system can be used for opening the cavity and adjusting the discharge port. It makes changing spare parts easier and reduces time and human labor.

Product parameters

| Model | Rotor spce(mm) | Feed opening(mm) | Maximum feeding size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) |

| PF1010 | 1000×1050 | 400×1080 | 350 | 50-80 | 75 | 2455×2086×2800 |

| PF1210 | 1250×1050 | 400×1080 | 350 | 60-120 | 110 | 2590×2050×2810 |

| PF1214 | 1250×1400 | 400×1430 | 350 | 80-160 | 132 | 2590×2400×2810 |

| PF1315 | 1300×1500 | 860×1520 | 350 | 120-260 | 200 | 2930×2760×3050 |

| PFW1214Ⅱ | 1150×1400 | 1100×1430 | 500 | 130-200 | 132 | 2400×2310×2550 |

| PFW1315Ⅱ | 1300×1500 | 1200×1530 | 600 | 180-320 | 200 | 2700×2750×2800 |

| PFW1318Ⅱ | 1300×1800 | 1200×1830 | 700 | 240-400 | 250 | 2700×2870×2800 |

| PFW1415Ⅱ | 1400×1500 | 1450×1530 | 700 | 300-480 | 250 | 2900×2700×3000 |

| PFW1214Ⅲ | 1150×1400 | 570×1430 | 250 | 90-170 | 132 | 2550×2310×2100 |

| PFW1315Ⅲ | 1300×1500 | 625×1530 | 300 | 180-270 | 200 | 2960×2570×2380 |

| PFW1318Ⅲ | 1300×1800 | 625×1830 | 300 | 220-300 | 200 | 2960×2870×2380 |

| PFW1415Ⅲ | 1400×1500 | 800×1530 | 350 | 280-350 | 250 | 3120×2650×2660 |