Clirik’s ore crusher integrates cutting-edge crushing technology, ensuring efficient processing of stone materials through a meticulously designed crushing chamber. Compared to traditional equipment, it can increase crushing efficiency by more than 20% while reducing energy consumption, bringing higher output ratios and lower operating costs to customers. Whether it’s the recycling of construction waste or primary crushing in mining, Clirik’s ore crusher can easily handle both.

What types of ore crushing equipment are available?

Clirik’s ore powder crushing equipment typically features small footprint, high flexibility, ease of transportation, and operation. Here are some main categories of ore crushers:

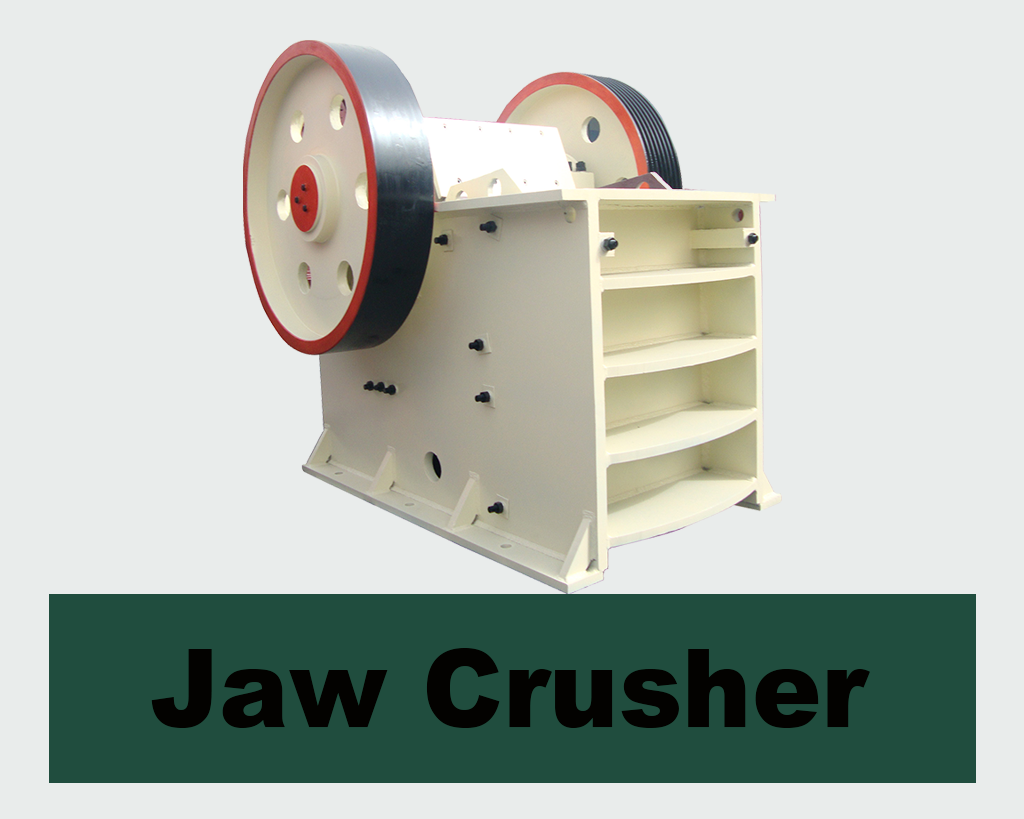

01 Jaw Crusher

As a primary crushing device, the jaw crusher is suitable for the initial crushing of large hard ores. It mainly achieves material crushing through the relative movement of two jaw plates.

Features: Large crushing ratio, uniform product size, simple structure, economical investment, and easy maintenance.

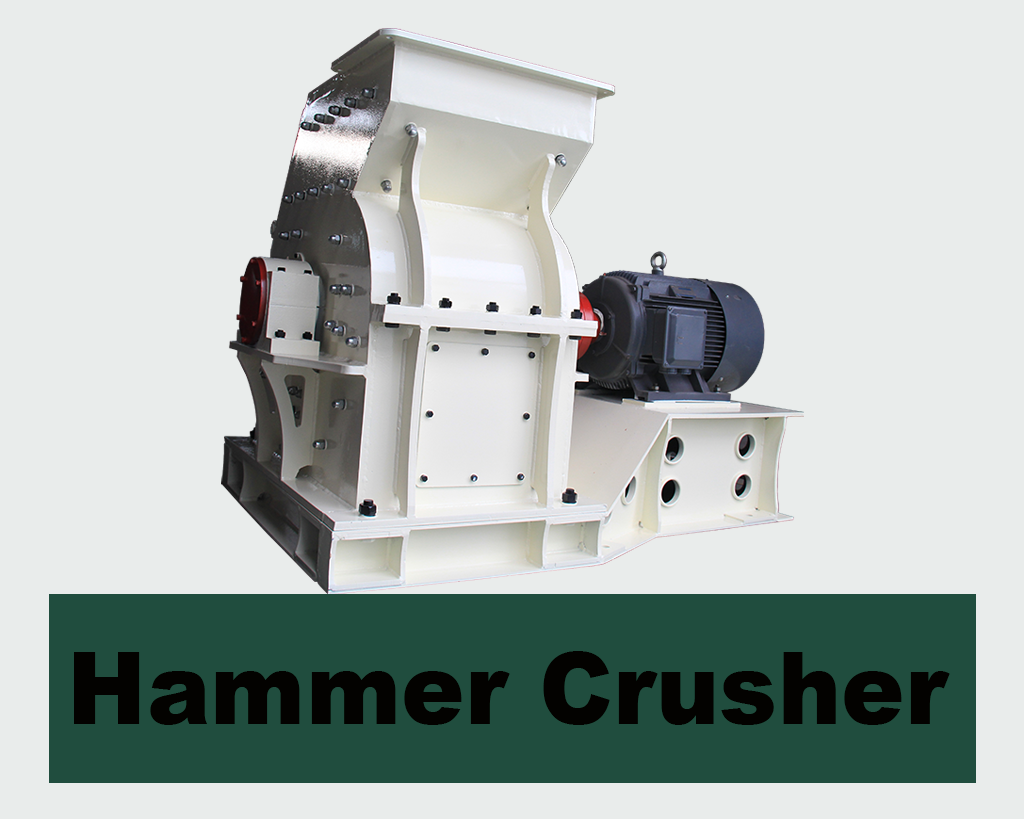

02 Hammer Crusher

Suitable for ore materials with medium hardness or lower. It completes the crushing by hitting the material with high-speed rotating hammers.

Features: High production capacity, low power consumption, uniform product size, and simple maintenance.

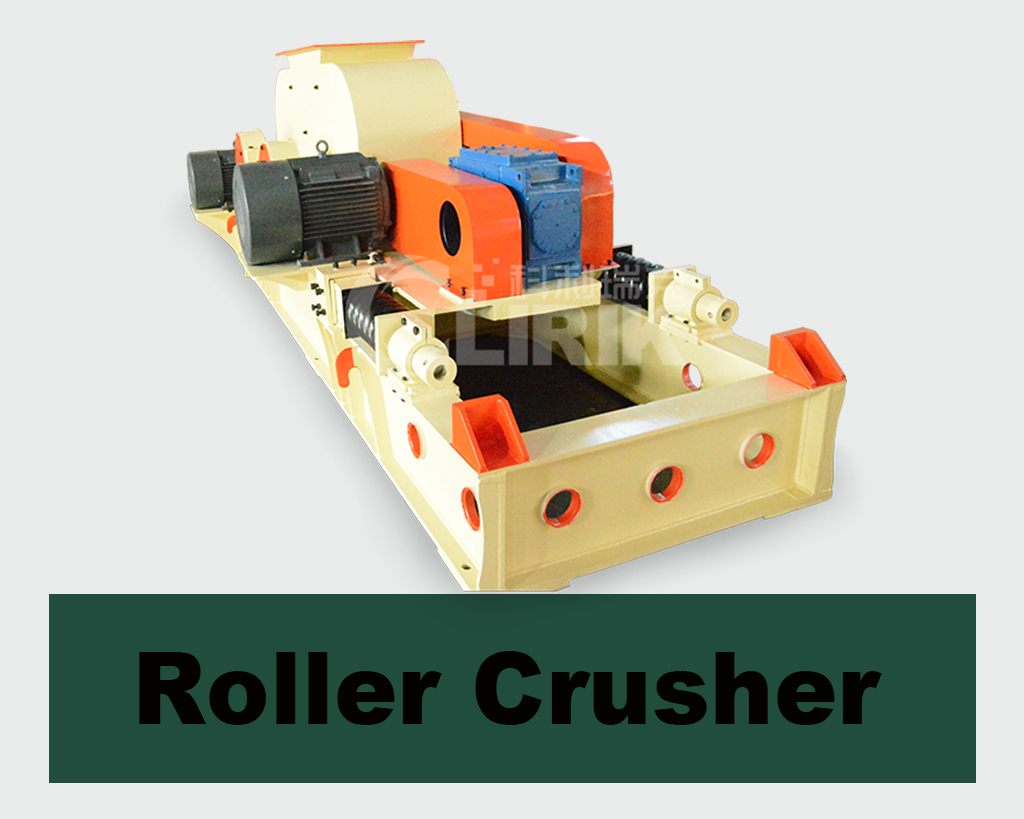

03 Roller Crusher

It applies pressure to the material through two or more parallel rotating rollers to achieve crushing, suitable for materials of medium hardness.

Features: High sand-making efficiency, low price, uniform particle size, and low noise.

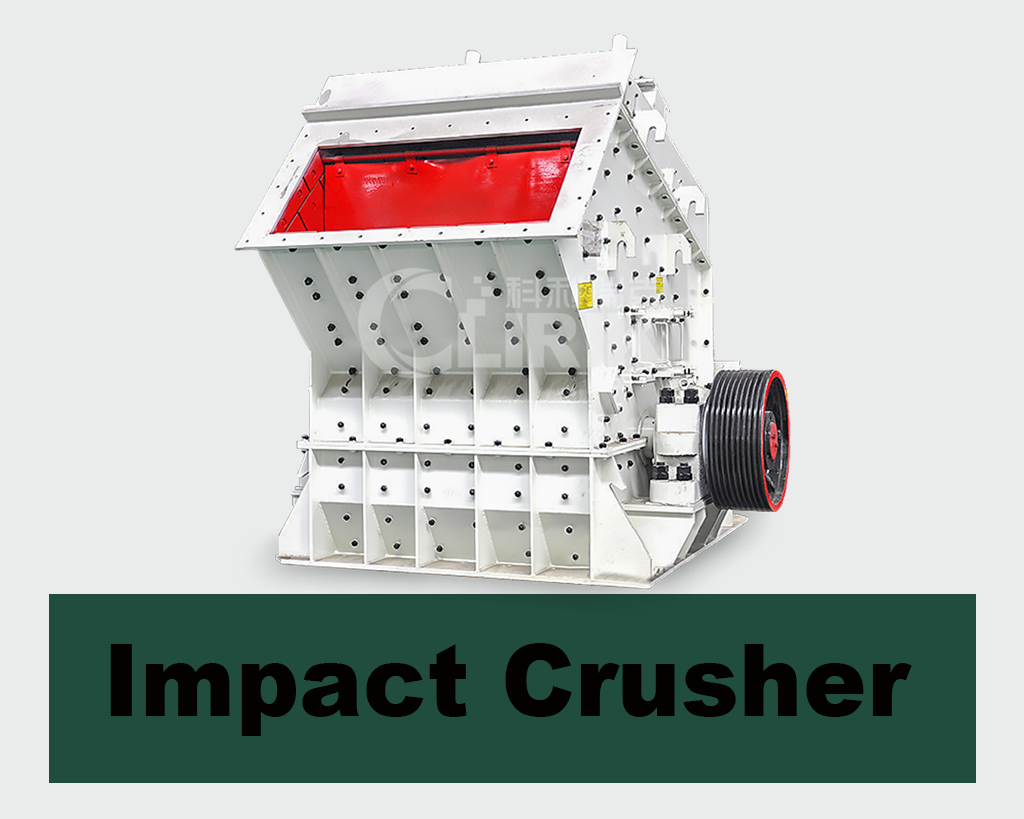

04 Impact Crusher

It uses a high-speed rotating rotor plate hammer to hit the material and completes the crushing through mutual collisions between materials. Suitable for materials from soft to medium hardness.

Features: Large feed opening, compact structure, and good product shape.

How much does an ore crushing machine cost?

Finding a high-yield, reliable small ore crusher is a key concern for customers regarding cost. The price of ore grinding machines varies due to multiple factors, including production capacity requirements, material characteristics, equipment configuration, and brand and service.

The price range varies from a few thousand yuan to over a million yuan, so clarifying needs and comparing different suppliers is key to choosing equipment with a higher cost-performance ratio.

In the fierce market competition, choosing the right equipment is crucial. Clirik, with its affordable price, excellent performance, and environmentally friendly low-consumption features, has become an ideal choice for ore crushers. The company has strong production capabilities and comprehensive after-sales service, ensuring the quality and service of the equipment.

Choosing Clirik means not only selecting an efficient production machine but also a partner that can quickly recover costs and continuously create value. Contact customer service now to get a free configuration plan and quote for the ore crusher.