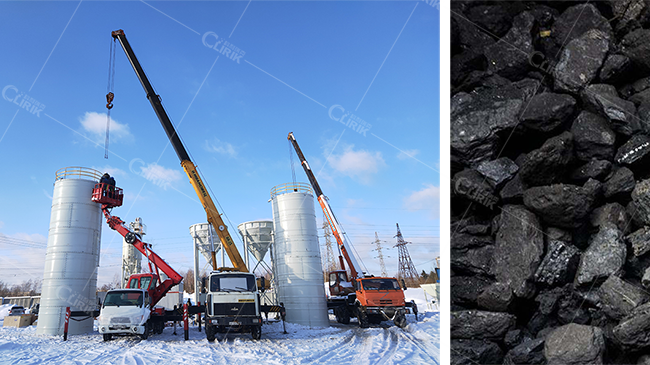

Clirik’s slag grinding project in Moscow has not only been successfully installed and put into production, but also received positive feedback from the customer, making it the highlight of the company’s cooperation cases.

The successful implementation of the project was made possible by the high-performance ring roll grinding mill and professional technical support provided by Clirik. Ring roller grinding mill, as a new type of grinding equipment, has the comprehensive mechanical crushing performance of roller pressure, grinding, impact, etc., and can smoothly produce ultra-fine powder with adjustable fineness between 80 mesh-3000 mesh.

The efficient operation of the equipment and stable product quality meet the strict requirements of the customer for slag treatment. Clirik’s equipment performance and service quality are highly evaluated by customers, who believe that the company’s equipment not only improves the production efficiency, but also reduces the production cost.

The working principle of the ring roller mill is to feed the material into the gap between the grinding wheel and the grinding rim, after the impact, extrusion and grinding of the grinding wheel and the grinding rim, the material is ground into powder. After the material is crushed in the first layer, it continues to fall into the second layer, the third layer, and even the fourth layer, and each layer further refines the material.

This multi-layer, multi-point crushing method makes the ring roller mill perform well in handling hard materials such as slag, with small iron content in the micro-powder, high output of fine powder, and continuous operation, which does not affect the oiling of the spindle bearing chamber during operation.

During the operation of the project, Clirik maintained close communication and collaboration with the customer. The company not only supplied the equipment, but also participated in the planning and design of the project, ensuring that the equipment met the customer’s specific needs. This customer-oriented service philosophy enabled Clirik to better understand the customer’s needs and provide a more customized solution.

The positive feedback from customers also reflects Clirik’s excellent reputation in the international market. The success rate of the Moscow project not only enhances the company’s brand image, but also lays a solid foundation for business expansion on a global scale. Recommendations and word-of-mouth from clients have become Clirik’s most valuable marketing resource.

In addition, Clirik emphasizes the sustainability of its projects. The company takes environmental protection and resource recycling into account during the project planning stage to ensure environmental compliance. This forward-looking project planning not only conforms to the global environmental protection trend, but also provides a guarantee for the company’s long-term development.

The technical features of the ring roller mill also include low noise, low vibration, high pressure, more fine powder, even wear of grinding rings and rollers, and long service life, which is 3-5 times longer than that of ordinary Raymond mill. These features make the ring roller mill more stable and reliable in operation, while also reducing maintenance costs and environmental impact.

The success of Clirik’s slag grinding project in Moscow has not only earned the company a good reputation in the market, but also laid a solid foundation for its business expansion worldwide. Through continuous technological innovation and high quality service, Clirik is confident to be the most reliable partner for its customers.