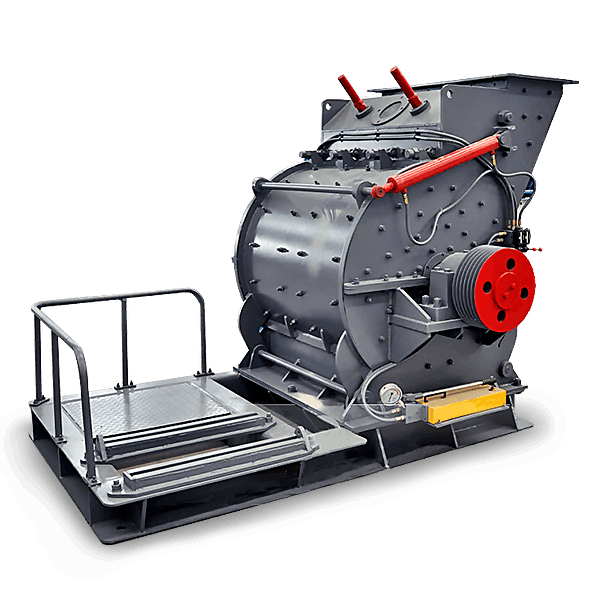

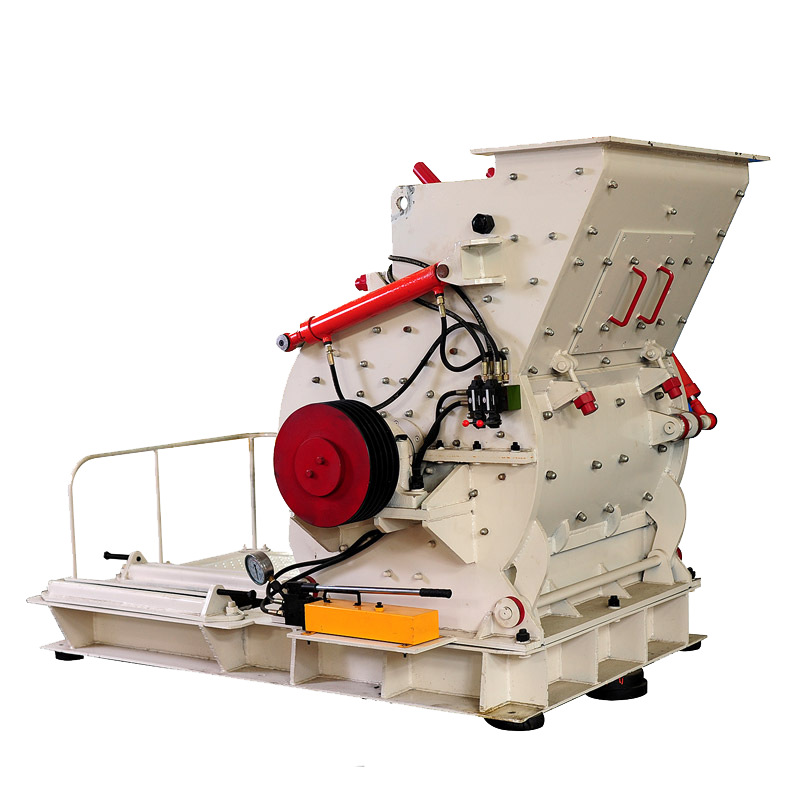

Scope and Application

Coarse Powder Hammer Mill is widely used in metallurgy, mining, chemical, cement, coal, sand-making, coal gangue, construction, refractory materials and ceramic industries.

Working Principle

The rotor assembly, a critical part of the crusher, is made up of turn plates, pin shafts, and hammers that are evenly distributed along the main shaft. The main unit, powered by a motor and connected via triangle belts, drives the main shaft, causing the rollers to rotate at high speeds, which is essential for the crushing process.

Large materials are fed into the crusher through the feed inlet and are immediately subjected to the high-speed hammers that perform the initial crushing. Post the primary reduction, the materials are forcefully thrown against the support iron, where they undergo further crushing until they are reduced to the desired size.

The crushed materials are then screened by the grate bars. Those that meet the size requirements pass through the gaps and exit the crusher, while the oversize materials remain in the crushing cavity for additional hammering and grinding until they reach the standard size. The final product size can be customized by adjusting the grate bars, and the gap between the rotors and the grate bars can be modified to suit various requirements.

To prevent the crusher from plugging, the materials to be crushed should contain no more than 20% water. This design consideration ensures smooth operation and prevents interruptions due to clogging, which is crucial for maintaining efficiency and productivity.

Structural Components

The European version coarse hammer crusher is composed of a robust frame, a rotor, support iron, and grate bars. The frame is meticulously crafted, divided into an upper and lower section, and welded together using steel plates for strength and durability. High manganese steel liners are integrated within the frame, designed for longevity and easy replacement once they have worn out.

Main Structure

★ Impact Plate

★ Side Fender

★ Hammer

★ Back Veneer

★ Sieve Plate

Advantages and Features

● High capacity and low power consumption

● Uniform particle size with high crushing and crushing ratio

● Simple structure

● Low investment, easy operation

Main Specification

| Type | PCC-75 | PCC-90 | PCC-132 |

| Rotor Diameter /mm | 750 | 900 | 1150 |

| Rotor Width / mm | 800 | 1200 | 1500 |

| Rotor Speed r/min | 800-1000 | 800-1000 | 550-800 |

| Feed head size /mm | 320*930 | 400*1200 | 500*1500 |

| Feeding size /mm | ≤50 | ≤60 | ≤80 |

| Finished Size /mm | ≤3 | ≤3 | ≤8 |

| Capacity t/h | 8-15 | 15-40 | 40-70 |

| Power /KW | 55-75 | 75-90 | 110-132 |

| Hammer Number (piece) | 18 | 32 | 32 |

| Overall Size L*W*H /mm | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |