Working Principle

component

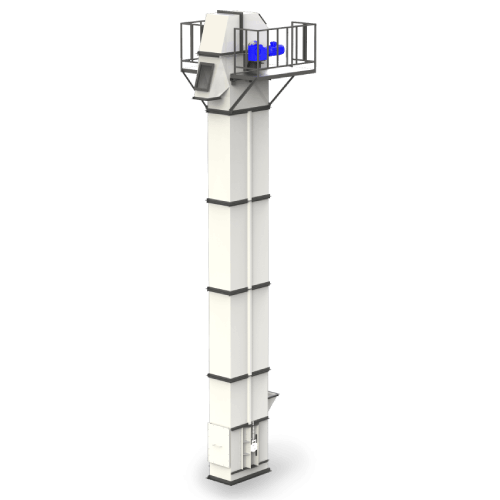

Bucket elevator consists of frame, drag part (conveyor chain), hopper, drive wheel (head wheel), feeding inlet (input inlet) and discharging outlet (output outlet).

Materials are fed into the elevator through a chute, which leads them to the hoppers for lifting.

The hoppers elevate the materials along the chain, moving upwards to the top of the elevator.

At the summit, materials are redirected down into the discharge outlet for conveyance to their destination.

The process occurs within the elevator frame, keeping dust contained and maintaining cleanliness.

The elevator uses a high-strength alloy steel chain and a long-lasting sprocket wheel for reliable performance.

Gravity devices maintain chain tension, preventing slippage and protecting the system from damage in case of hopper jams.

Advantages and Features

● High capacity. The capacity is 1 times higher than the HL bucket elevator in the same bucket width.

● Adopt packaged sprocket, consisted of wheel body, sprocket rim which are connected by high strength bolt. It is convenient to unscrew the bolt and change sprocket rim after the sprocket wheel wear to a certain degree, which can save material, reduce the maintenance costs.

● The heavy-duty lever tensioning device makes automatic tension be realized. Once installed, no need to adjust, and it can keep constant tension, ensure the normal operation and avoid the skid or take off the chain.

● Stable lifting height, reliable operation, low noise, easy maintenance.

● The conveying capacity of improved model is 30% higher than normal models.

● The drag part is high strength low alloy steel chain whose lifetime is long. After proper heat treatment, the steel chain has very high tensile strength and wears resistance.

Technical Parameters

| Type | TH200 ZH | TH200 SH | TH315 ZH | TH315 SH | TH400 ZH | TH400 SH |

| Capacity (m3/h) | 17.87 | 28.6 | 35 | 59 | 58 | 93 |

| Hopper volume (L) | 1.5 | 2.4 | 3.75 | 6 | 5.9 | 9 |

| Hopper Interval (mm) | 500 | 500 | 512 | 512 | 512 | 512 |

| Chain steel diameter x pitch (mm) | Φ14*50 | Φ14*50 | Φ18*64 | Φ18*64 | Φ18*64 | Φ18*64 |

| Chain breaking strength (KN) | ≥190 | ≥190 | ≥320 | ≥320 | ≥320 | ≥320 |

| Speed (r.p.m) | 63.22 | 63.22 | 44 | 44 | 37.6 | 37.6 |

| Input size (mm) | 25 | 25 | 35 | 35 | 40 | 40 |