Scope and Application

The equipment is broadly applicable, particularly adept at processing calcium carbonate in its various forms and grinding tough materials like quartz and zircon. It handles softer minerals smoothly and is ideal for producing fine cement and alumina. Also, it’s designed for efficient slag processing from cement and steel industries.

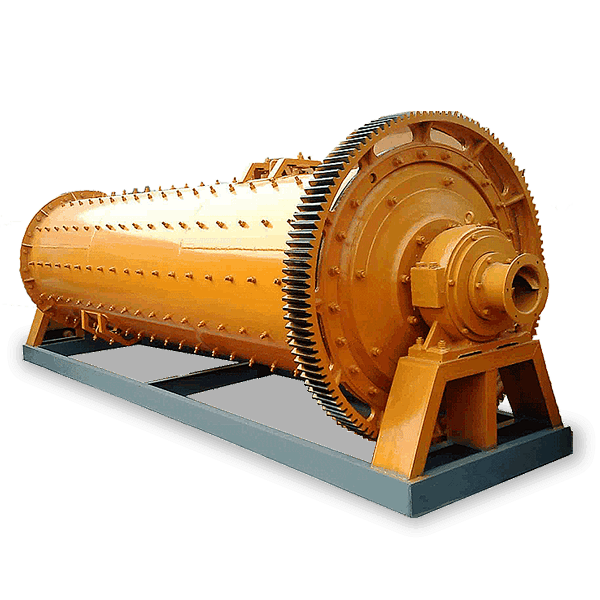

Working Principle

After undergoing initial coarse crushing, materials are directed into the ball mill through a mechanism that allows for controlled feeding. This step ensures a steady and regulated flow of materials into the mill, optimizing the grinding process.

Inside the ball mill, the grinding media, which are often balls or rods, are set in motion by the kinetic energy derived from the mill’s rotation. These media repeatedly impact and grind the material, reducing it to a fine powder.

The finely ground material is then discharged through the mill’s tail end, falling into a collection trough. From this point, the material is drawn into a classifier by the action of negative pressure.

In the classifier, the material is separated based on particle size. Fine powder that meets the grade specification is collected by cyclones or dust collectors, while larger, undersized particles are expelled from the classifier’s base and sent back to the mill for additional grinding.

This process of grinding and classification is continuous, ensuring a consistent output of material that meets the required fineness. The system is designed to maximize efficiency and minimize waste, with only the finest particles being collected for use.

Advantages

The ball mill features a special design that carefully proportions the grinding media to achieve the desired fineness of grind. This precise media mix ensures that the materials are efficiently reduced to the ideal particle size, optimizing the grinding process for various applications.

The ball mill utilizes a continuous control system for feeding, ensuring the stability of the feed rate. This consistent input is crucial for attaining the highest grinding efficiency, as it maintains a uniform load within the mill.

The mill’s hopper is equipped with high-quality level indicators that guarantee the automated control of the production process.

These indicators provide real-time data, ensuring that the mill operates at optimal levels with minimal human intervention.

The entire grinding line is managed by a fully automated control system that ensures stable machine loads and guarantees low energy consumption.

The entire grinding line is managed by a fully automated control system that ensures stable machine loads and guarantees low energy consumption.