Ball mills, as crucial equipment in industrial production, require meticulous attention during their trial run phase. Various issues often arise during this process, and if not addressed promptly, they can severely impact the normal operation of the equipment and shorten its service life. This article will discuss the common problems encountered during ball mill trial runs and their respective solutions.

01 Loose Liner Bolts

Loud, rhythmic knocking suggests improperly tightened bolts. Locate and tighten them to prevent liner collision with the mill body.

02 High Bearing Temperature

An increase in temperature of the ball mill and motor bearings beyond the specified limit. Exceeding temperature limits can be due to various factors:

Ensure that the type of lubricating oil used in each component aligns with the manufacturer’s guidelines for the equipment.

Determine if there is any sign of degradation in the lubricating oil and grease.

Verify that the lines are not obstructed and that the lubricating oil is flowing directly into them.

Inspect to see if the bearing’s side clearance is too tight or if there is excessive play between the bearing and the shaft.

Assess whether the rolling bearing grease levels are either excessive or insufficient, and replenish as necessary according to established standards. Typically, maintaining grease levels between 1/3 to 1/2 of the bearing’s clearance is recommended.

Review the sealing mechanisms at both ends of the grinding body’s hollow shaft.

03 Motor Speed Reducer Vibration

Misalignment or uneven bolt tightening can cause this. Adjust clearance and tighten bolts symmetrically.

04 Ball Mill Vibration

Installation Issues: Ensure mill and reducer axes are aligned. Re-adjust if needed.

Foundation Settlement: Monitor and adjust for any significant foundation movement.

05 Reducer Noise

Slight knocking or grinding may indicate minor issues. Stop the mill if noise persists or worsens. Check balance and intermediate wheel installations.

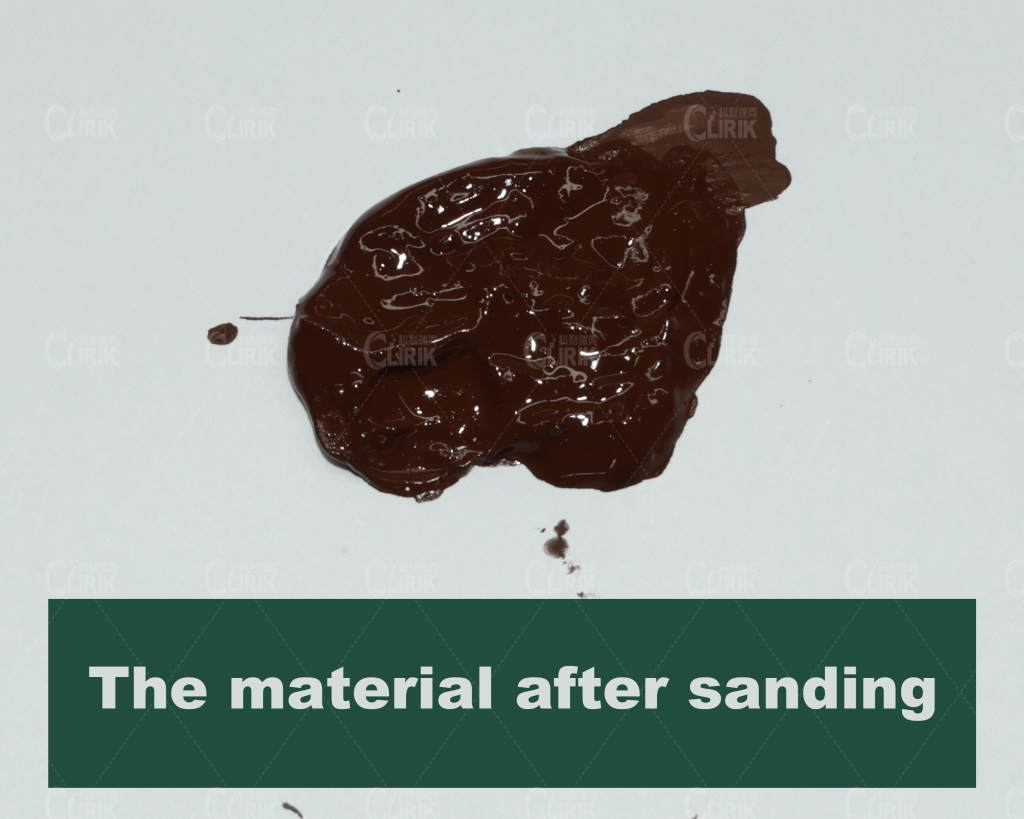

By conducting thorough inspections and maintenance on key components such as the liner bolts, bearings, lubrication systems, couplings, and reducers, various issues that may arise during the operation of ball mills can be effectively prevented and resolved. This not only extends the service life of the equipment but also ensures the smooth progress of production. On October 10, 2024, Clirik successfully completed a 500kg iron ore grinding trial using the HGM80A micro powder grinding mill, providing strong assurance for the high efficiency and stability of production.