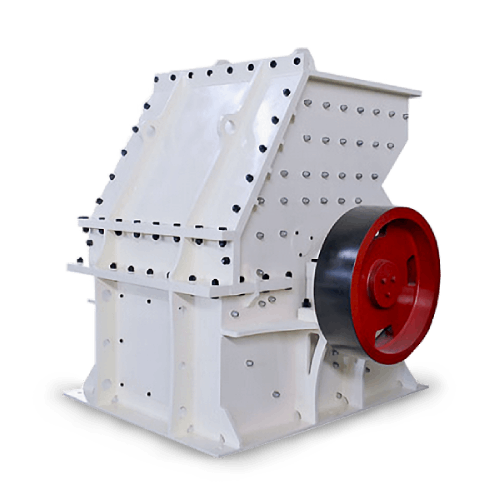

Hammer Crusher

Hammer crusher is a device that uses the impact of a high-speed rotary hammer to break materials.

Input Size:

<400mm

Output Size:

0-25mm

Capacity:

3-60t/h

Scope and Application

The hammer crusher is mainly applied for crushing in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials and ceramics.

metallurgy

mining

chemistry

cement

construction

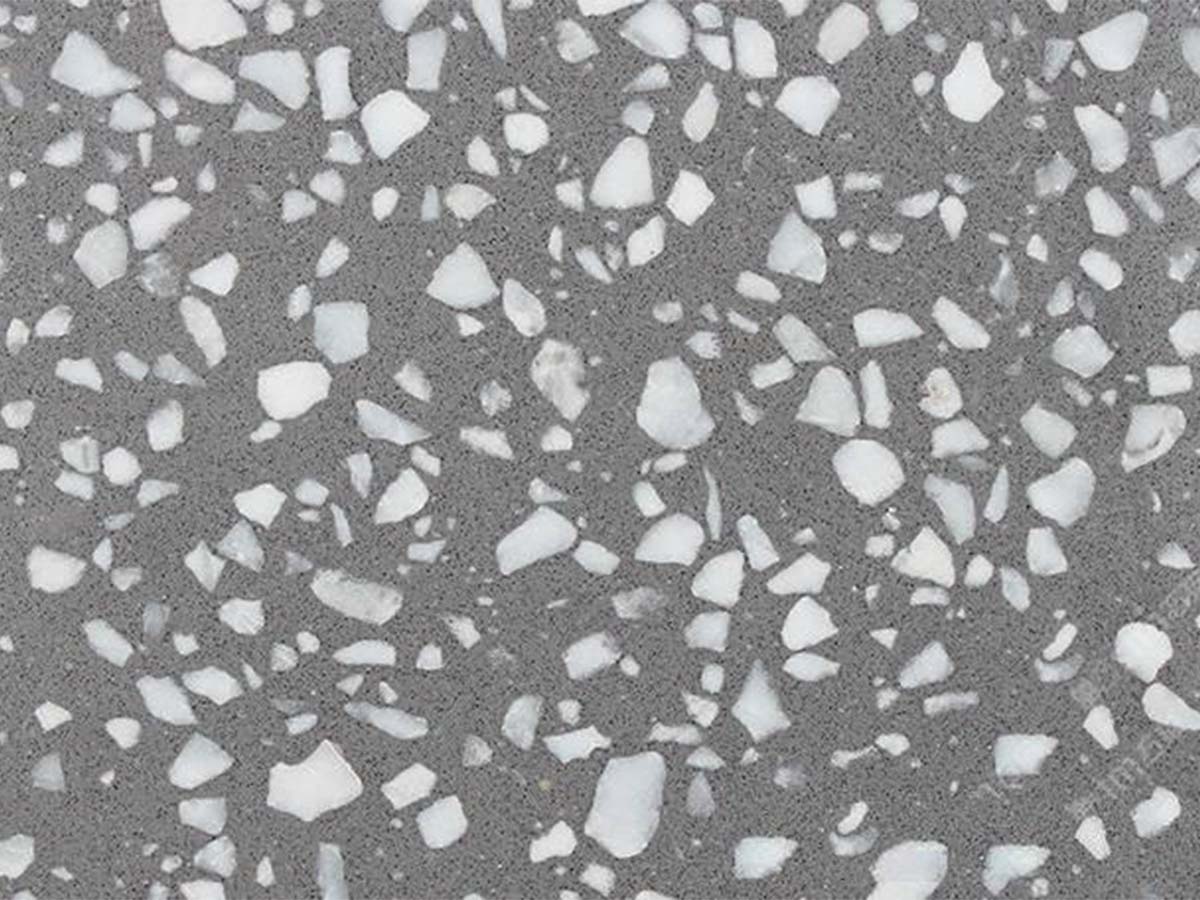

The hammer crusher can crush hard and soft ores into medium or small size, such as barite, limestone, gypsum, terrazzo, coal, slag, and up to 100 different kinds.

barite

limestone

gypsum

terrazzo

coal

Technical Advantages

The hammer crusher boasts an impressive crushing capacity, capable of handling substantial volumes of materials in a single operation. Its high-speed rotary hammers ensure a swift and powerful impact, breaking down materials with remarkable efficiency.

This feature is particularly beneficial for industries requiring large-scale production, as it significantly reduces the time and effort needed for the crushing process.

The hammer crusher boasts an impressive crushing capacity, capable of handling substantial volumes of materials in a single operation. Its high-speed rotary hammers ensure a swift and powerful impact, breaking down materials with remarkable efficiency.

This feature is particularly beneficial for industries requiring large-scale production, as it significantly reduces the time and effort needed for the crushing process.

One of the key technical advantages of the hammer crusher is its ability to produce uniformly sized particles.

The combination of striking, impacting, cutting, and grinding actions ensures that the output is consistently fine and meets the required specifications.

This uniformity is crucial for subsequent processes in various industries, where particle size can affect the quality and performance of the end product.

The hammer crusher features a simple yet robust design that facilitates easy operation and maintenance. Its structure is composed of essential components that work in harmony to achieve efficient crushing.

The simplicity of the design not only reduces the likelihood of mechanical failure but also minimizes the complexity of maintenance routines, making it an ideal choice for long-term industrial use.

The low investment required for the hammer crusher, coupled with its low maintenance nature, makes it an economically viable option for businesses.

The use of high manganese steel for liners and hammers contributes to a longer service life, reducing the frequency of replacements and associated costs.

Moreover, the adjustable grate bars and rotor gap allow for customization to suit various material types and sizes, enhancing the crusher’s versatility and value.

The hammer crusher is designed with environmental considerations in mind.

Its enclosed structure helps to contain dust and noise pollution, ensuring that the operation complies with environmental regulations.

This feature is particularly important for industries that are increasingly focusing on sustainable practices and reducing their ecological footprint.

Working Principle

Frame and Liners

The hammer crusher is composed of a sturdy frame divided into an upper and lower part, joined by steel welding.

High manganese steel liners are embedded for durability, easily replaceable when worn.

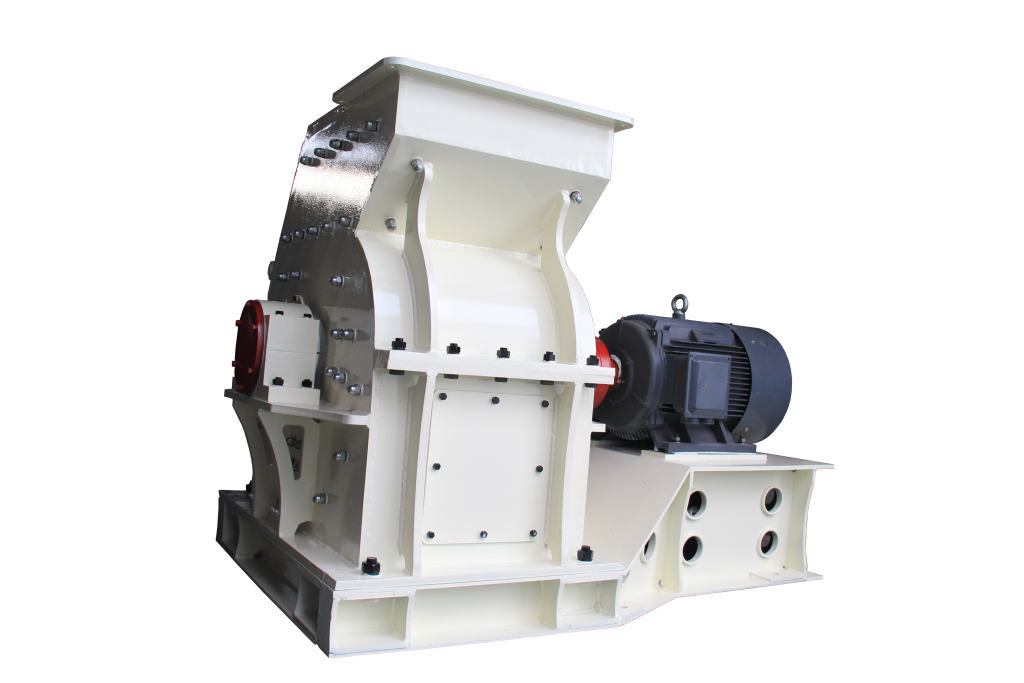

Rotor and Hammers

The rotor, complete with a turn plate, pin shafts, and hammers, spins at high speed powered by the motor.

The hammers, propelled outward by centrifugal force, are poised to shatter the materials.

Materials are fed into the crusher and subjected to high-speed hammer impacts, reducing them to smaller sizes through striking, cutting, and grinding.

Qualified crushed materials pass through the grate bars while oversized ones remain for further processing until they meet the required size.

The final particle size is adjustable by changing the grate bars, allowing customization to various applications.

Parameters

| Model | PC400x300 | PC600x400 | PC800x600 | PC1000x800 |

| Rotor Diameter (mm) | 400 | 600 | 800 | 1000 |

| Rotor Width (pieces) | 300 | 400 | 600 | 800 |

| r/min | 1100 | 1000 | 960 | 980 |

| Input Size (mm) | <100 | <200 | <350 | <400 |

| Output Size (Kw) | 0—10 | 0—20 | 0—25 | 0—25 |

| Capacity (t/h) | 3—8 | 8—15 | 15—45 | 40—60 |

| Power (kw) | 11 | 18.5 | 45 | 75 |

| Hammer Number (pcs) | 16 | 20 | 28 | 30 |

| Weight (ton) | 0.5 | 1.6 | 4 | 6.5 |

| Dimension (mm) | 855*795*860 | 1150*1095*1230 | 2360*1490*1415 | 3072*1720*2121 |